TEL:+86 13179668188 E-MAIL:alina@volsn.com

PTP PLAIN TROLLEY

Key Features

- Rotating Suspension Design

- Manual Push Operation

- Adjustable Beam Width

- Smooth & Safe Running

- Compact, Low-Headroom Design

- Multiple Capacities & Customization

Typical Specifications

-

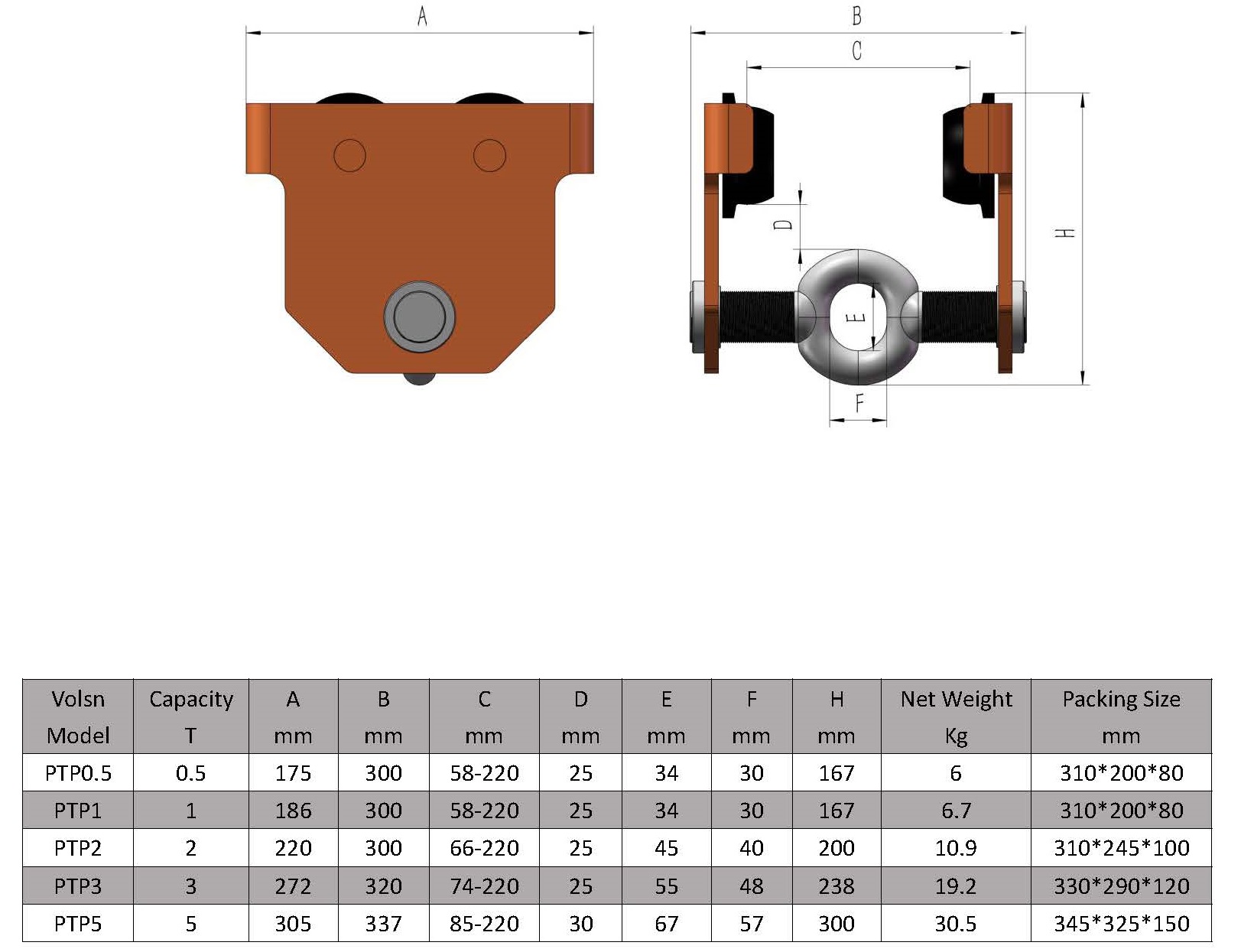

Capacity: 0.5T / 1T / 2T / 3T / 5T (customizable)

-

Beam Width Range: 40–300 mm (adjustable)

-

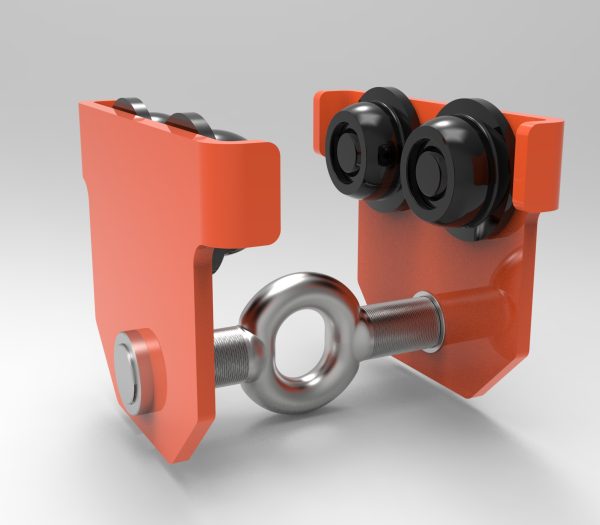

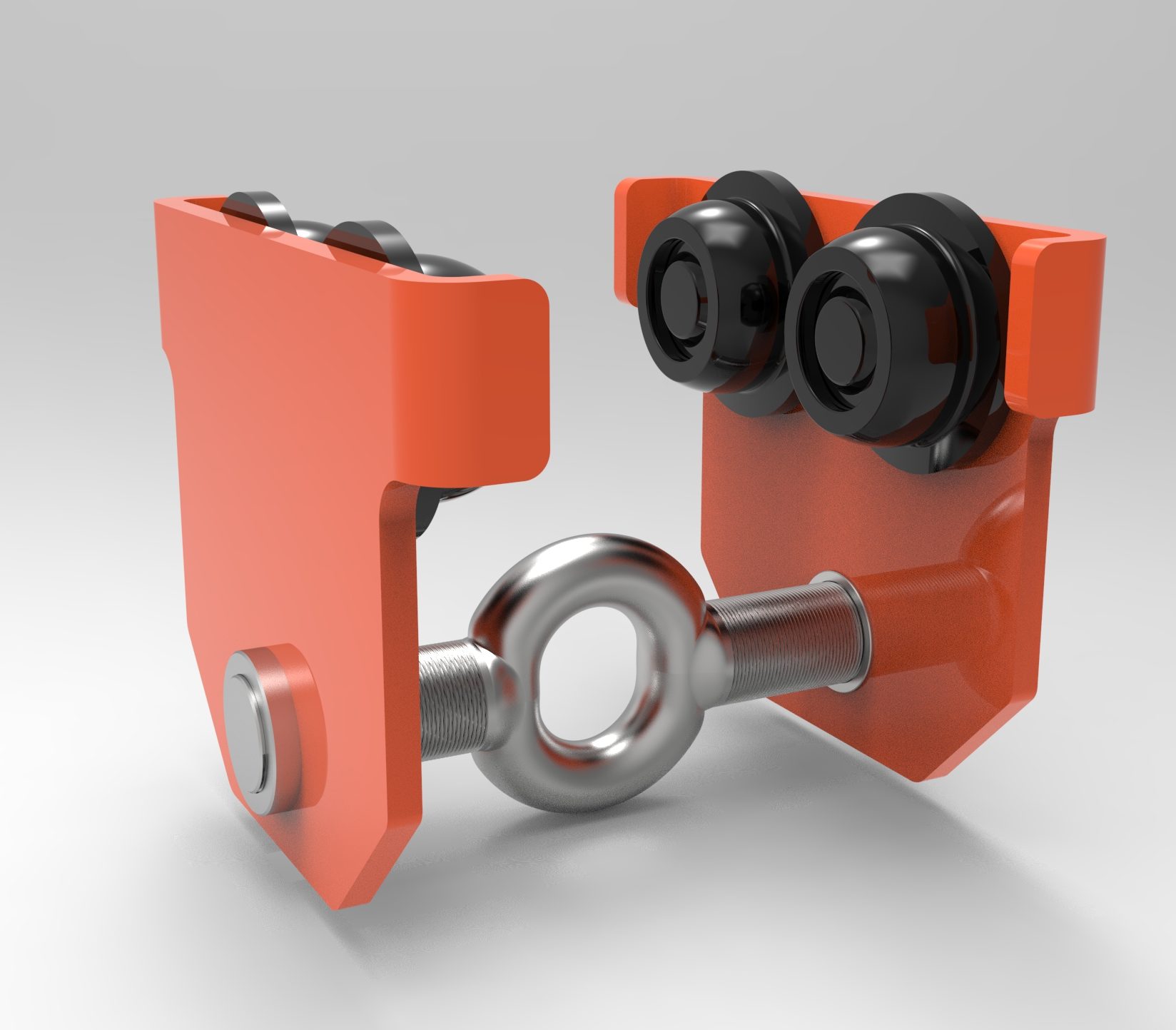

Connection Type: Rotating eye bolt or swivel hook (optional)

-

Safety Features: Anti-drop plates, sealed bearings, end stop blocks

Rotating PTP PLAIN TROLLEY

Flexible Movement · Precise Positioning · Reliable Performance

Product Overview

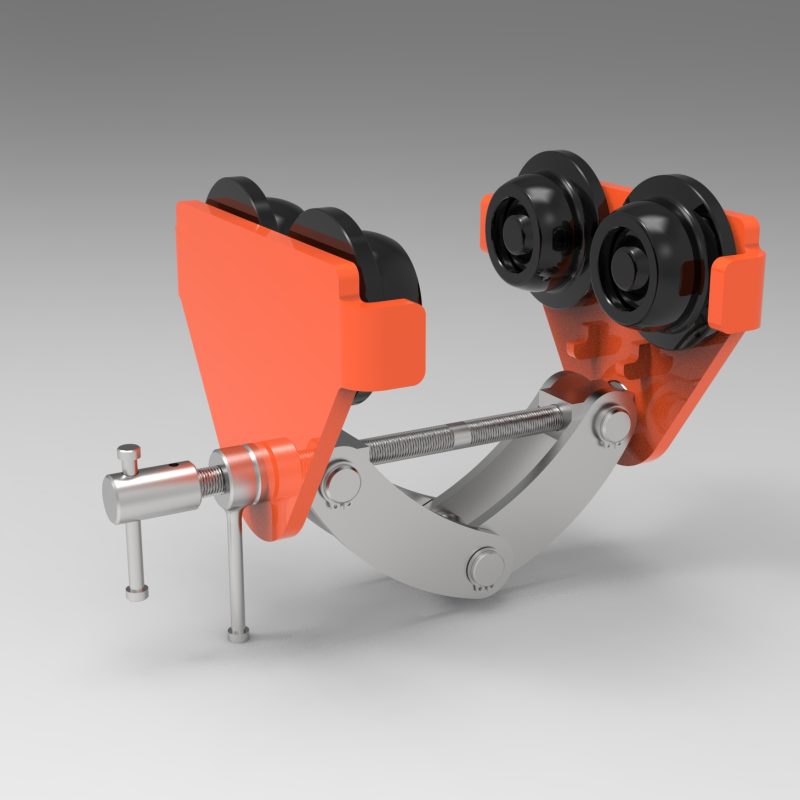

The Volsn Rotating PTP PLAIN TROLLEY is designed for flexible load handling along I-beams or H-beams.

Its rotatable suspension connection allows the trolley to swivel freely, making it easier to lift or move loads in any direction. The push-type design enables smooth manual operation without the need for gears or electric drives — ideal for workshops, warehouses, and on-site maintenance environments with limited space.

Key Features

-

Rotating Suspension Design

The rotatable hanging point allows for flexible directional adjustment, enabling operators to align loads precisely without repositioning the trolley. -

Manual Push Operation

Simple, cost-effective, and easy to use — the trolley can be pushed manually along the beam, providing efficient movement and control. -

Adjustable Beam Width

The trolley width can be quickly adjusted to fit a variety of I- and H-beams. Easy installation with secure locking ensures compatibility across multiple beam types. -

Smooth & Safe Running

Equipped with precision bearings, anti-drop plates, and safety end stops, ensuring stable and secure travel even under heavy loads. -

Compact, Low-Headroom Design

The compact structure minimizes headroom loss, making it suitable for confined spaces or low-clearance workshops. -

Multiple Capacities & Customization

Available from 0.5 ton to 5 ton capacity.

Custom options include stainless steel material, anti-corrosion coatings, or special labeling and packaging upon request.

Applications

-

Equipment installation and mold handling in workshops

-

Load movement in warehouse and logistics systems

-

Maintenance and repair work in factories or sites with limited space

-

Cleanroom or anti-corrosion environments (stainless version available)

Why Choose Volsn

-

20 years of OEM experience in lifting clamps and material handling solutions

-

Own factory with robotic welding and automated production lines

-

Short production cycle and flexible order quantities

-

Custom design support for labeling, packaging, and beam compatibility

-

Committed to providing high-quality, reliable, and customizable lifting equipment to global partners