TEL:+86 13179668188 E-MAIL:alina@volsn.com

TC GEARED TROLLEY

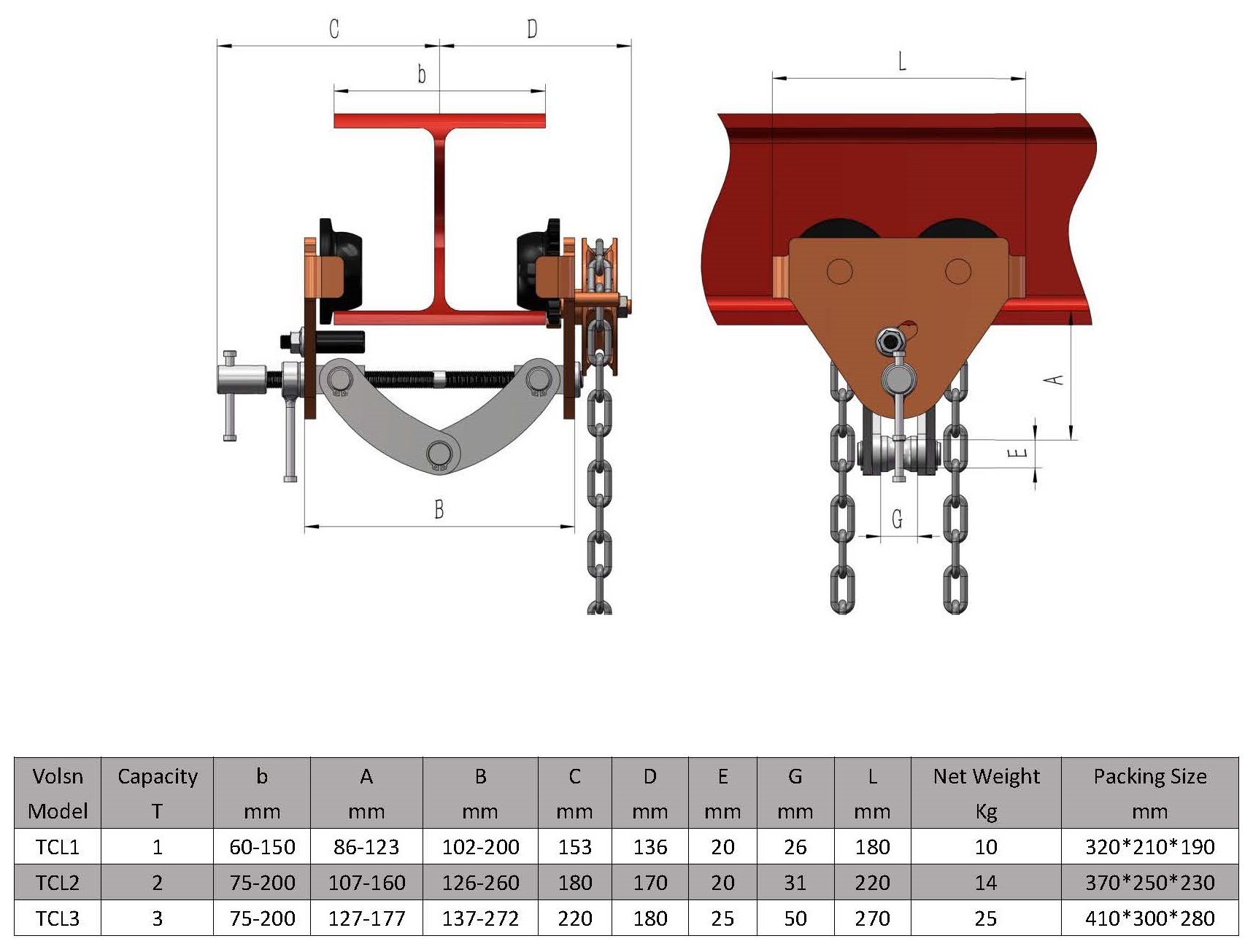

Typical Specifications

-

Capacity: 1T / 2T / 3T (customizable)

-

Beam Width Range: 40–300 mm adjustable

-

Drive Type: Geared hand chain drive

-

Safety Devices: Anti-drop plates, locking nuts, end stops

Applications

-

Manufacturing workshops and assembly lines

-

Machinery maintenance and mold handling

-

Warehouse lifting and material transportation

-

Construction and site equipment positioning

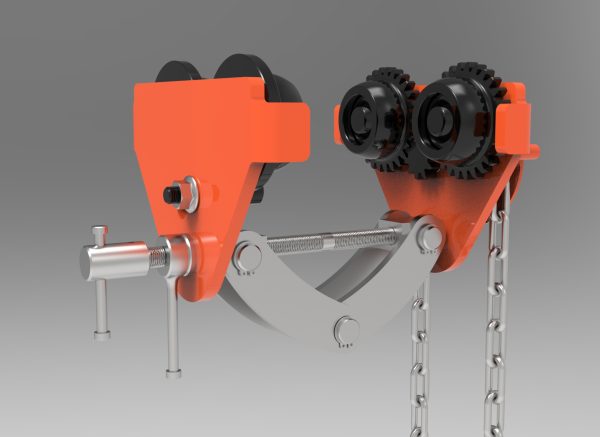

TC GEARED TROLLEY

Precision Control · Adjustable Width · Safe & Smooth Operation

The Volsn TC GEARED TROLLEY is designed for precise load positioning and smooth travel along I-beams or H-beams.

Featuring a hand chain drive system and an adjustable clamping arm, this model allows effortless movement of heavy loads while adapting to different beam widths. Ideal for factories, workshops, and construction sites where controlled movement and stability are essential.

Key Features

-

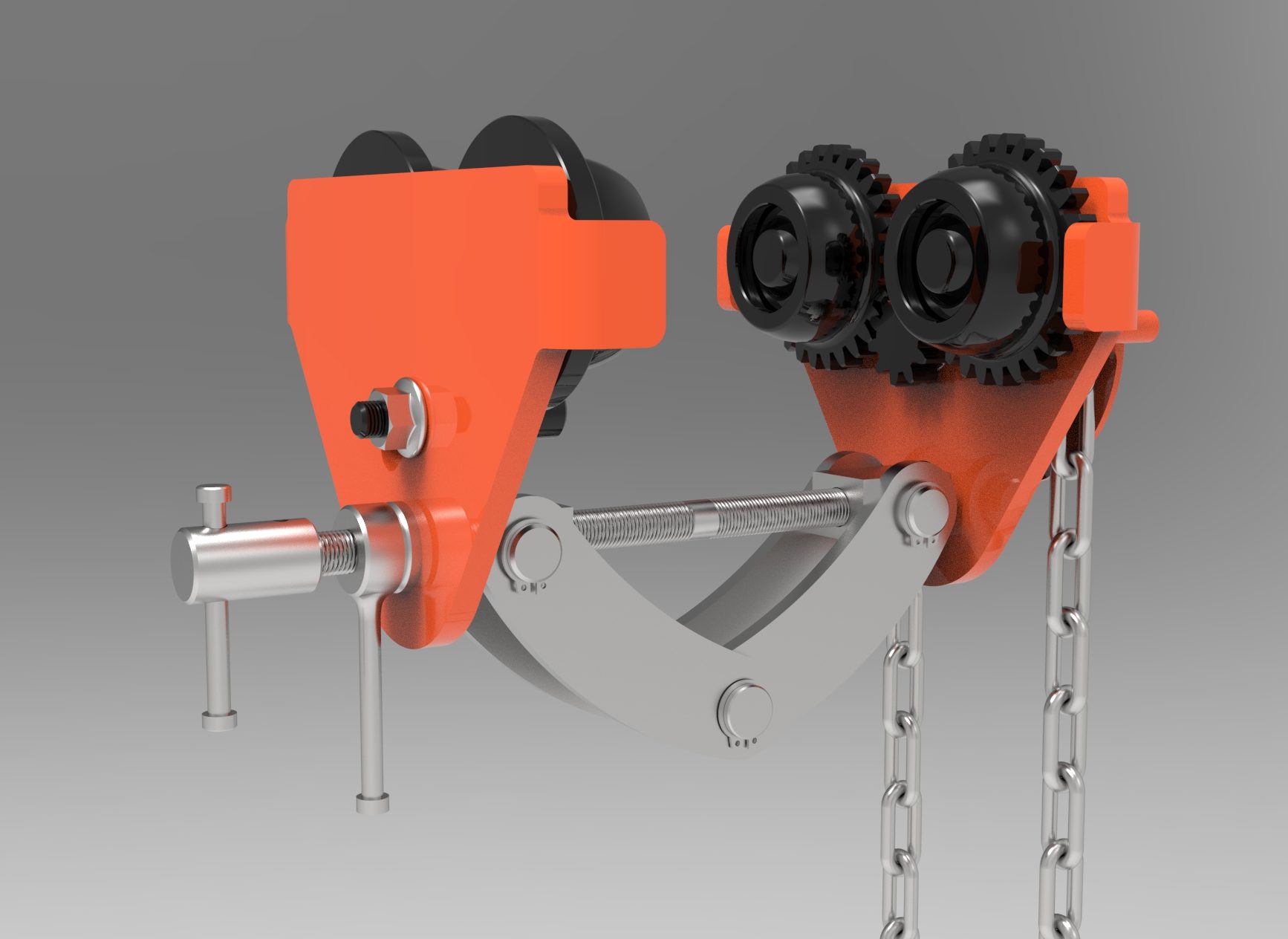

Precision Geared Operation

The hand chain mechanism drives the trolley wheels through a robust gear system, providing smooth, controlled movement even under heavy loads. -

Adjustable Beam Clamp Design

The width-adjustable beam clamp fits a variety of I- and H-beams. It can be quickly secured using the threaded adjustment bar, ensuring a tight and reliable grip. -

Stable & Safe Structure

Equipped with high-strength side plates, anti-drop lugs, and safety nuts to prevent derailment and enhance durability under continuous use. -

High-Quality Bearings

Sealed ball bearings minimize friction and maintenance, ensuring stable running and longer service life. -

Durable Industrial Finish

Powder-coated carbon steel body with corrosion-resistant surface treatment, suitable for both indoor and outdoor environments. -

Customizable Options

Load capacity, beam width, color, labeling, and packaging can all be customized to meet OEM or project-specific requirements.

Why Choose Volsn

-

20+ years of OEM manufacturing experience in lifting clamps and beam trolley systems

-

In-house production with robotic welding and precision machining

-

Short production cycles and flexible MOQ for OEM/ODM orders

-

High-quality welding and assembly for long-lasting performance

-

Full customization available — from beam size to surface finish